If you’re new to ceramic grills or a new Primo owner, a Primo Ceramic Grill is one of the most versatile outdoor cookers in the world. You can use it as a grill, an oven, a roaster, or a smoker with a simple adjustment to the air flow and cooking configuration. Below is an overview of their grills and the basics for using and enjoying their ceramic grills. Primo Ceramic Grills can be used as a grill, an oven, a roaster, or a smoker.

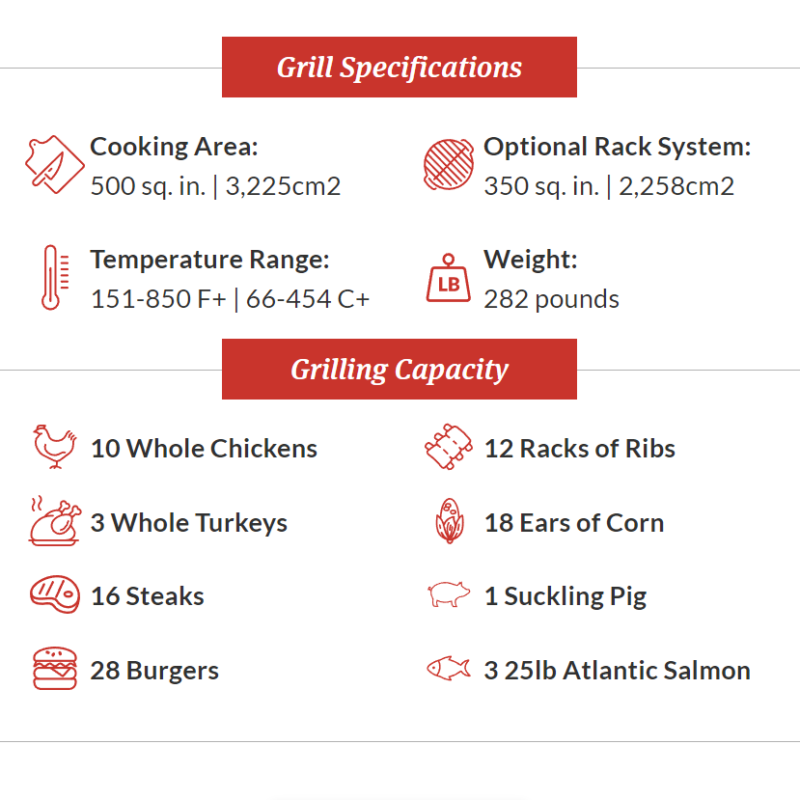

Primo’s XX-Large Charcoal Grill provides the largest cooking area and the patented oval shape offers superior cooking efficiency and accessibility. Serve food to an entire party, prepare large meals for the family, or have the space to grill nearly anything just for yourself.

Primo Ceramic Grills Featured Products

Made in the USA

From Start to Finish, See how Primo Ceramic Grills are made in their factory.

- Slip Room – The finest raw materials are sourced from all over the southeastern United States. Raw materials are combined with water to form a pourable slurry to form Primo grills and accessories.

- Robot – The robot casts the basic ceramic components of the Primo. This robot can cast over 300 pieces a day!

- Drying – The grill components are left to dry for 1 to 2 days. They then move on to the conveyor to be glazed. Each Primo is sanded by hand to remove any imperfections.

- The Kiln – Grills are loaded onto the kiln cars and moved into the kiln for firing at 2400 degrees Fahrenheit (1315 degrees Celsius). It takes a full day to complete the firing process.

- Final Inspection and Assembly – Each Primo goes through a rigorous inspection process. Grills that pass inspection are assembled here and shipped all over the world.